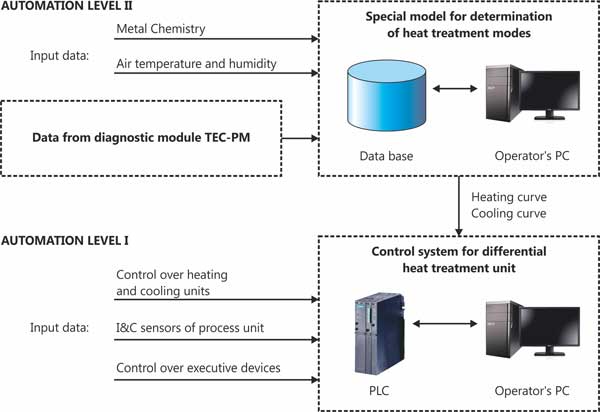

1st level - Control System for Unit and Executive Mechanisms.

2nd level - Special model for determination of heat treatment mode depending on metal chemistry and rail type.

In order to provide fine adjustment of heat treatment modes there is developed a diagnostic module checking heating and cooling parameters. It is a measuring rail with host module checking temperature during the heating and cooling processes at different points of rail top and base ("black box").

Accuracy of heating and cooling modes during the heat treatment process is controlled by checking following parameters:

- Rail inlet temperature and rail temperature after each heating zone and after main cooling zone, as well as ambient air temperature and humidity

- Rail position, speed and travel force for ТЕС-DТ

- Air pressure and flow rate in air blowers, top and base cooling casings water pressure and flow rate (g/sec) for each injection valve

- Operational parameters of heating equipment and mechanical systems.

Data logging, indication of limit values of controlled parameters, generation of a report on heat treatment mode mismatch in case of significant parameter overriding.