Heat treatment line for railroad casting enables heat treatment of cast bars - side frame and bolster - for equalizing chemical inhomogenei-ty and grain size and obtaining mechanical properties specified by OST-32-183-2001.

When using this heat treatment technology a full phase recrystallization of 20GFL and 20GL steels occurs. By grain refining, relieving internal stresses and reducing structure inhomogeneity heat treatment facilitates an increase in plasticity and viscosity of products compared to mechanical properties received after casting.

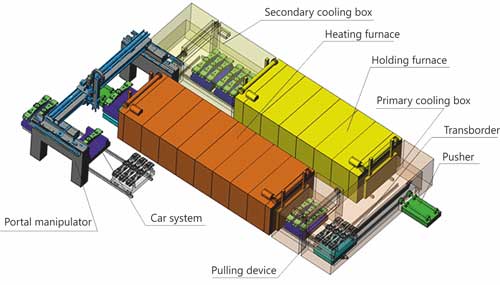

Process Equipment

- Heating furnace

- Original cooling box

- Holding furnace

- Secondary cooling box

- Transportation system: cars, transborders, pushers, pulling head, rail tracks; car fixing devices.

Technical Parameters

|

Capacity, pcs/h

|

10

|

|

Furnace heating

|

Electric

|

|

Operation mode

|

Three-shift

|

|

Annual working time fund, h/y

|

6000

|

|

Technical features of blanks to be heat treated

|

|

Overall dimensions, mm

|

|

|

Side frame

|

2413х671х580

|

|

Bolster

|

2590х480х486

|

|

Maximum wall thickness, mm

|

35

|

|

Weight, kg

|

|

|

Side frame

|

399

|

|

Bolster

|

520

|

|

Material

|

20G1FL, 20GL steel as per GOST 977-88

|

|

Chemical composition, %

|

С - 0.14...0.21; Si - 0.5...0.8; Mn - 0.9...1.3;

V - 0.07...0.13; S - up to 0.03; Р - up to 0.035

|

|

Utilities

|

|

Voltage, V/Hz

|

~380/50

|

|

Water, kgf/cm²

|

5

|

|

Temperature, °С

|

12 - 25

|

|

Compressed air, kgf/cm²

|

6

|