|

The first batching line for ferroalloy production was supplied and commissioned in 2002. In 2002-2008 more than 20 process lines and control systems have been commissioned (Implemented Projects) in order to produce such ferroalloys as: Ferrochrome (FeCr), ferrosilicon (FeSi), ferrovanadium (FeV), ferromanganese (FeMn), ferromolybdenum (FeMo).

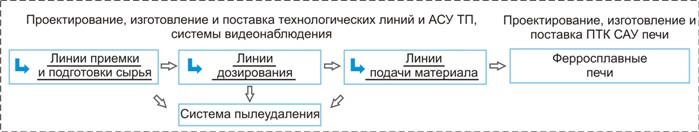

SME Tomsk Electronic Company can offer the following for ferroalloy production:

|

|

| |

|

Features of Process Lines

For continuous supply:

- Error in batching out of the maximum production limit is 0.5 - 1% as per GOST 30124-94:

- For continuous batching supporting the preset proportion in the batching mode when batching intermittent doses

- Supporting accuracy of components proportion not worse than 1%

|

|

For batching:

- Accuracy of batching within 1% as per GOST 10223-97

- Replacement of vibrating feeders with belt ones (those providing delivery of the materials directly from the hopper to the belt feeder)

- Reduction of noise and dust level in the line operation area

|

|

Charge Materials Techniques

- Intermittent (materials are supplied by batchers to the intermittent conveying line)

- Continuous (materials are supplied continuously by belt feeders to the continuous conveying system)

- Combined (materials are supplied continuously or intermittently to the conveying system operating either continuously or discontinuously)

|

|

Special Software

- Algorithm aimed to adjust batching and supply of components including correction in case of external disturbances (poor convergence, choking up, changes in the density, material fractions etc.)

- Algorithm for proportion adjustment (components combination) during materials handling supporting the ratio of components not worse than ± 1 % (ASAD)

- Algorithm for desoxidant supply adjustment basing on its humidity and correction of ore materials supply depending on the content of the main component

|

|

When some upgrade is implemented, the commissioning is divided into stages (with no shutdown of the main production) individually for each project.

|