| |

|

|

Charge Material Transportation and Supply Systems

|

When designing lines for material batching and supply, including warehouse facilities, one uses various transportation equipment unified into one transportation system for different productions.

Charge materials transportation systems provide continuity of production and consist of storage units and conveying devices aimed to transport charge materials from the places of their storage, preparation, homogenization and batching to metallurgical plants.

Conveying systems can be based on process equipment manufactured by SME Tomsk Electronic Company and by some other manufacturers.

Equipment applied:

- Scraper tubular conveyor - manufactured by Contec

- SICON conveyor - manufactured by Continental ContiTech Scandinavia AB - Sweden

- Belt dryer and heat unit - manufactured by FORMZ

- Vibrating screen GIL-051 - manufactured by Gornye Mashiny

- Effective mixer - manufactured by Kulonenergomash

- Retractable conveyor - manufactured by Belokholunitsky Mashzavod

- Auger mixer - manufactured by Stroymekhanika etc.

There are the following types of transportation systems:

- Intermittent conveying lines

- Continuous conveying systems

|

|

Intermittent Conveying Lines

|

|

Intermittent conveying lines include processing, batching and transportation equipment, providing cyclic loading of charge materials into metallurgical plants. Intermittent conveying systems include devices of intermittent action (wagons, mine cars, cranes, monorail trucks, movable lifting devices etc).

Operation cycle of devices of intermittent action include loading, operation travel, discharge and return travel (for instance, furnace hoisting machine for supplying charge materials into blast furnace).

The following projects have been implemented basing on the equipment by SME TEC:

- KFLZ, technical upgrade of ferromolybdenum production shop

- ChMZ, Upgrade of Blast Furnace #2

|

|

|

|

|

|

|

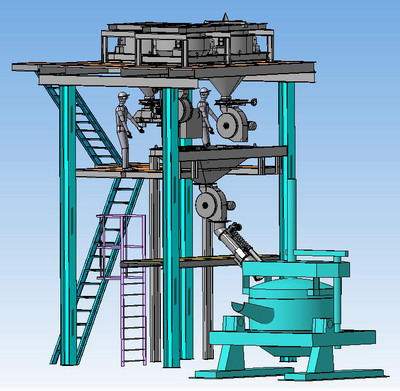

KLFZ - Section of Material

Supply Into Furnace |

|

KLFZ - Sector of Charge Briquetting |

|

ChmZ - Skip Pit |

|

|

Equipment for Intermittent Conveying Systems, Manufactured by SME TEC

|

|

Upon Customer's request some individual modifications of the equipment are possible.

|

|

|

Continuous Conveying Systems

|

|

Continuous conveying lines include processing, batching and transportation equipment, providing continuous loading of charge materials into metallurgical plants. Continuous conveying systems include continuous devices (conveyors, elevators, vibrating chutes etc).

Devices of continuous action transport charge materials along the certain route with no stops (for example, supplying bulk materials into storage bins of the converter shop).

The following projects have been implemented basing on the equipment by SME TEC:

- NKMK (UPC)

- NTMK, Upgrade of Blast Oxygen Shop #1

- AZF

|

|

|

|

|

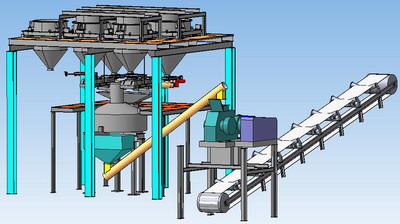

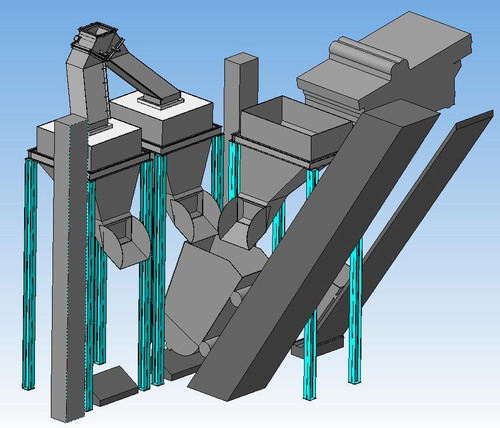

| Upgrade of Blast Oxygen Shop #1, Standby Conveyor, OAO NTMK |

Fire Resistant Production, OAO NTMK |

Upgrade of Blast Oxygen Shop #1, Standby Conveyor, OAO NTMK |

|

|

Equipment for Continuous Conveying Systems, Manufactured by SME TEC

|

|

Upon Customer's request some individual modifications of the equipment are possible.

|

|

|

When unifying into one automated system, conveying systems are divided into sections (transportation systems, which belong to a certain process part, their limits are usually identified by the material storage facilities) and conveying routes (transportation route within process sector where material flow is strictly limited by process and intermediate bins location). This division depends on production technology and control algorithm.

|

|

|

|

|

|