| |

|

|

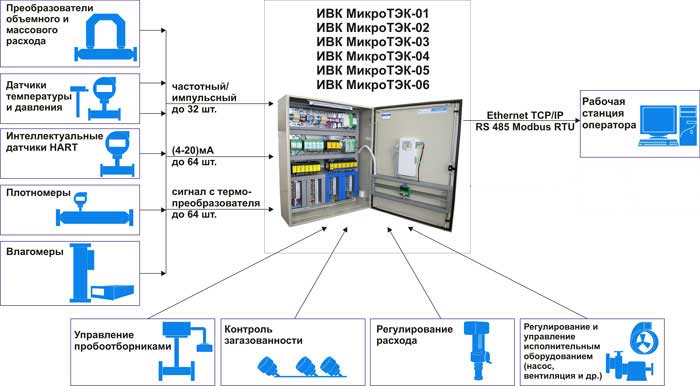

IVK MicroTEK-01, MicroTEK-02, MicroTEK-03, MicroTEK-04, MicroTEK-05, MicroTEK-06

|

Purpose

|

IVK MicroTEK-01

|

- is aimed for accounting of crude and commercial oil

(GOST R 8.595, GOST R 8. 615, MI 2693) and formation water

|

|

IVK MicroTEK-02

|

- is aimed for accounting of natural and associated petroleum gas

(GOST R 8.586.1-5, GOST 30319.0-3, GSSSD MR 113)

|

|

IVK MicroTEK-03

|

- is aimed for metering commercial oil in the tank farm up to five lines

|

|

IVK MicroTEK-04

|

- is aimed for economic accounting of material flows

|

|

IVK MicroTEK-05

|

- is aimed for metering formation water up to 16 lines

|

|

IVK MicroTEK-06

|

- is aimed for metering natural gas up to 16 lines

|

|

|

IVK MicroTEK is used as a part of information-processing system:

- for quality and quantity metering systems for crude and commercial oil, gas and water to provide routine and commercial recording

- for metering units of product flows at oil refinery, petrochemical and metallurgical companies

- for stands testing flow meters recording volume and weight

- for units for oil loading into railway, trucks and ships

- for oil and oil products metering in tank farms

- for material resources, gas, water accounting systems

- for other industries

|

|

Advantages

- Built-in spark-proof enclosures

- Hook up to field equipment with no auxiliary equipment

- Supply of transducers hooked up to the system

- Flexible system configuration, matching any metering system structure

- Configurable and parameterized software

- Unauthorized access protection. Multilevel password system

- Hot swapping of modules and system extension option with non-stop accounting by product modularity

- Hot backup, including computing device, measuring channels and automated workstation

- One computing unit enables up to 24 lines to be accounted

|

|

|

| |

|

Basic Features

|

Parameter

|

Value

|

|

Measuring channels parameters

|

|

Standardized current signal measuring channel:

|

|

Measuring range, mA

|

4..20

|

|

Maximum number of channels in IVK, pcs

|

64

|

|

Temperature sensor signal measuring channel:

|

|

Temperature range, °С:

|

|

|

- Chromel/copel thermocouple (NSC of K type as per GOST R 8.585-2001)

|

from -100 to +400

|

|

- Chromel/alumel thermocouple (NSC of L type as per GOST R 8.585-2001)

|

from -100 to +400

|

|

- Copper thermoresistance NSC TSM-50, TSM-100 as per GOST 8.625-2006)

|

from -100 to +200

|

|

- Platinum thermoresistance

(NSC TSP-50, TSP-100, Pt-100, TSP-500 as per GOST 8.625-2006)

|

from -100 to +300

|

|

Maximum number of channels in IVK, pcs

|

64

|

|

Pulse-frequency signal measuring channel:

|

|

Measuring range, Hz

|

1..10 000

|

|

Signal amplitude range, V

|

0.03…30

|

|

Maximum number of channels in IVK, pcs

|

32

|

|

Metrologic Parameters

|

|

Limits for absolute permissible error of metering:

|

|

Standardized current signal, mA

|

±0.015

|

|

Thermal converter signal, °С

|

±0.05

|

|

Limits for relative permissible error of metering:

|

|

Pulse frequency and period, %

|

±0.002

|

|

Pulse quantity, %

|

±0.025

|

|

Input signal frequency metering channel, %

|

±0.01

|

|

Ratio of pulse quantity per time interval, %

|

±0.01

|

|

Limits for relative permissible error to convert input electric signals into actual values:

|

|

Oil and gas volume, %

|

±0.025

|

|

Oil and gas gross weight,%

|

±0.05

|

|

Conversion coefficient for oil volume meter, %

|

±0.025

|

|

Conversion coefficient for oil weight meter, %

|

±0.04

|

|

Technical Parameters

|

|

AC voltage, V

|

187..242

|

|

Operation temperature ranges, °С

|

from +1 to +50

|

|

Explosion protection marking

|

[Ex ia] IIC

|

|

|

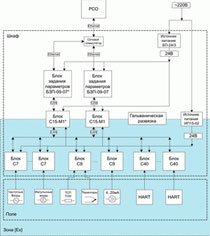

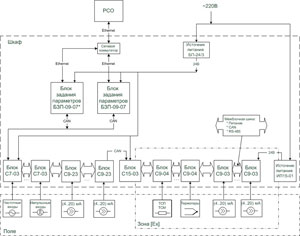

IVK MicroTEK Components

IVK MicroTEK-01, MicroTEK-02, MicroTEK-03, MicroTEK-04, MicroTEK-05, MicroTEK-06 are modular systems. Depending on object structure, number and types of input signals, IVK is composed of various metering and control units. At present components for two casing modifications OKW and Phoenix are manufactured. However designed IVK MicroTEK-01, -02, -03, -04, -05, -06 perform the above functions. Moreover casing modification Phoenix has a number of advantages:

- High density of measuring channels due to modules less areas

- More compact size of IVK MicroTEK electric cabinet

- Easier assembly, enhanced reliability and no electric connection between flow meters since inter-modular connection bus is available

- Programming operation modes for flow meters (no mechanical links), which enhances system reliability, speed and convenience when operating modules

- Increasing general number of measuring channels of IVK MicroTEK due to optimization of data exchanging protocol through CAN interface

|

|

IVK MicroTEK-01, -02, -03, -04, -05, -06 are composed of the following types of modules:

|

|

IVK MicroTEK-01, MicroTEK-02, MicroTEK-03, MicroTEK-04, MicroTEK-05, MicroTEK-06 units are attached according to the following structure charts:

|

|

|

|

|

IVK MicroTEK-01, -02, -04

OKW cased units connection layout

|

|

IVK MicroTEK-01, -02, -03, -04, -05, -06

Phoenix cased units connection layout

|

|

|

Supplies Options

Except for supply of computing units MicroTEK-01, MicroTEK-02, MicroTEK-03, MicroTEK-04, MicroTEK-05 MicroTEK-06 in casings to be installed into the Customer panels, SME TEC offers complete delivery of information processing systems (IPS) on the IVK MicroTEK basis.

IPS on the IVK MicroTEK-01, -02, -03, -04, -05, -06 basis include the following:

- IVK MicroTEK panel

- Operator's automated workstation "Wizard" on the basis of the office PC or of industrial version with individually configured software

|

|

|

|

Auxiliary equipment, gas contamination control systems, regulating and control systems can be installed into IVK MicroTEK panel. Panel size can be determined on the basis of object structure, number of included in IVK MicroTEK units and Customer's individual demands.

It is possible to supply the following packaged equipment: IPS on the IVK MicroTEK basis (including workstation), RemTEK electric drives for stop and control valves (packaged delivery including valves is possible), gas contamination control systems on the basis of GSM Gas Detectors.

IVK MicroTEK-01, -02, -03, -04, -05, -06 is a metrological supported system with certified software, calibration technique, using standard reference and certified metering technique.

|

|

Up

|

|

|

|

|

|