|

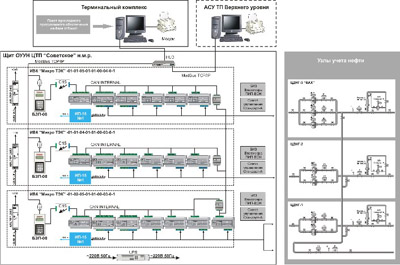

Data processing system based on IVK MicroTEK-01 for three metering stations with common checking line

|

|

|

|

Facility: Metering Station

|

|

|

Meter run unit:

- turbine flow converter (TPR)

- differential pressure transducer

|

Discharge manifold:

- pressure transducer

- temperature transducer

|

|

Quality assurance unit(BKK):

- mixer

- flow moisture meter

- automatic sampler

|

Common checking line:

- turbine flow converter (TPR)

- temperature transducer

- pressure transducer

|

|

Functions:

-

collection and processing of information from primary converters for flow, density, humidity content, temperature, pressure and differential pressure

- automatic control, indication and warning of metered parameters limit values

- calculation, indication and transfer of recoded parameters to operator's work station (RSO) through Ethernet Modbus TCP/IP interface

- Supply of all primary converters hooked up to the system

- control over automatic samplers as per GOST 2517-85

- mode of metrological characteristics check (KMKh) with control turbine flow transducer and turbine flow transducer with mechanical displacement prover

- drawing up, storage and printing of control charts

- storage and printing of two-hour, shift, daily and monthly reports, archives and event and emergency logs

- uninterrupted power supply to system during two hours by central power supply cutoff

|

|

Features:

- check of metrological characteristics of all metering stations with general control line

- general operator's work station (RSO) based on InTouch software applications package

|

|

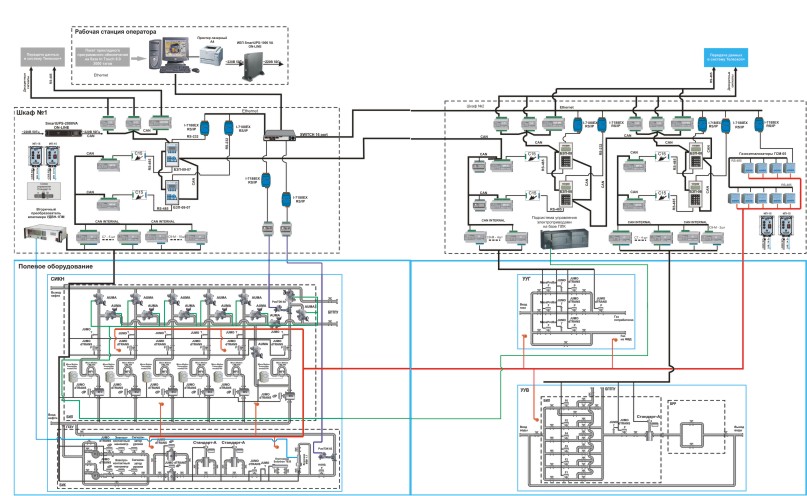

Data processing system based on IVK MicroTEK-01 for metering station, gas and water metering stations

|

|

|

|

Facility: Metering Station

|

Facility: Gas Metering Station

|

|

Meter run unit (six MR):

- mass flow converter (PMR) - 6 pcs.

- differential pressure transducer on filter - 6 pcs.

- pressure transducer - 6 pcs.

- temperature transducer - 6 pcs.

- ball valve with electric drive - 20 pcs.

|

Meter run unit (three MR):

- mass flow converter (PMR) - 3 pcs.

- pressure transducer - 4 pcs.

- temperature transducer - 3 pcs.

- ball valve with electric drive - 2 pcs.

|

|

Discharge manifold:

- pressure transducer - 1 pcs.

- temperature transducer - 1 pcs.

- control valve with RemTEK-02 electric drive - 1 pcs.

|

Facility: Water Metering Station

|

|

Quality assurance unit (BKK):

- turbine flow converter (TPR) - 1 pcs.

- pump - 2 pcs.

- pressure difference transducer on pump - 2 pcs.

- electric-contact manometer - 2 pcs.

- ultrasonic alarm device - 2 pcs.

- pressure difference transducer on filter - 1 pcs.

- automatic sampler - 1 pcs.

- pressure transducer - 1 pcs.

- temperature transducer - 1 pcs.

- flow humidity meter - 1 pcs.

- flow densitometer - 1 pcs.

|

Meter run unit(six MR):

- ultrasonic flow converter - 6 pcs.

- pressure transducer - 1 pcs.

- temperature transducer - 1 pcs.

- automatic sampler - 1 pcs.

|

|

Flow control unit:

- pressure transducer - 1 pcs.

- temperature transducer - 1 pcs.

- ball valve with electric drive - 2 pcs.

|

|

Functions:

- collection and processing of information from primary flow transducers for mass, temperature, pressure and differential pressure, humidity and density

- control over ventilation by means of GSM-05 gas detectors digital outputs by elevated concentration of burning gases (actuation of threshold 1 and 2)

- calculation, indication and transfer of recoded parameters to operator's work station through Ethernet Modbus TCP/IP interface and to "Teleskop+" telemechanics system through RS-485 Modbus RTU interface

- supply to all primary converters hooked up to the system

- control over automatic samplers as per GOST 2517-85

- uninterrupted power supply to system during two hours by central power supply cutoff

- calibration and check-out modes for metrological characteristics (KMKh) of volume and mass flow converters with reference flow meter and calibration rig, drawing up and printing of KMKh and calibration reports

- Drawing up, storage and printing of two-hour, shift, daily and monthly reports, archives and event and emergency logs

- supply disconnection to instrumentation transducers located on metering stations by external fire-fighting system actuation

- control over pumps of quality assurance unit from operator's working station

- flow control through meter run unit from RSO by means of control over RemTEK-02 electric drives

- control over AUMA electric drives for stop valves by means of digital signals (24 V)

|

|

Features:

- Hot reservation of computers and parameters display units for UUN, UUG and UUV

|

|

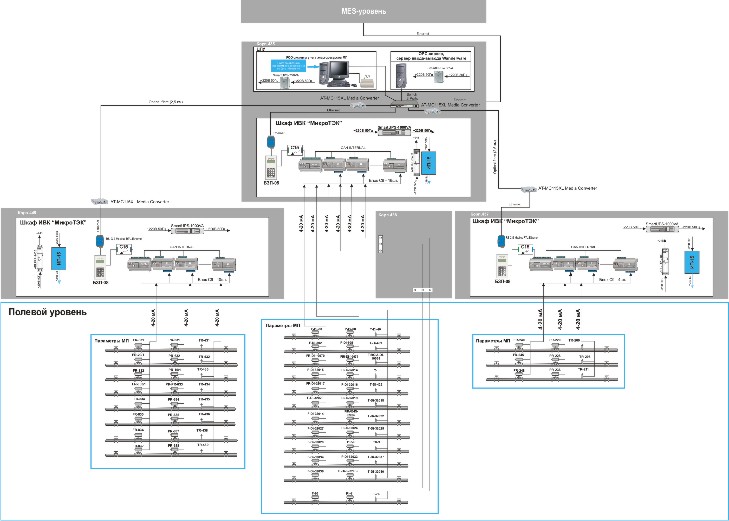

AIS Khozuchet power resources metering system based on IVKMicroTEK-04 for high-pressure polyethylene (PEVD) manufacturing

|

|

|

Automation Object:

PEVD manufacturing automation object is a set of pipelines of accounting flows of the following facilities:

- workshop # 408 - polyethylene manufacturing

- workshop # 409 - polyethylene manufacturing

- workshop # 410 - polyethylene manufacturing

- workshop # 411 - manufacturing of polyethylene and technical carbon based materials

Total amount of routine metered material flows of all workshops is 31.

|

|

Functions:

- collection and processing of information from differential pressure and temperature transducers

- automatic control, indication and warning of limit values of metered parameters

- nulling of cumulative counter on operator's signal

- Drawing up, storage and printing of hourly, shift, and daily reports and archives

- measurement, calculation, indication and delivering parameters to RSO which are necessary for gas and liquid metering

- system time correction particularly by means of higher level software as per Modbus RTU protocol

- diagnostics and indication of field equipment operability

- system information protection from illegal access using passwords and lock words

- data transfer to MES-level system of PEVD manufacturing through Ethernet network

- manual input of physico-chemical parameters of power resources

|

|

Features:

- distributed metering system over facility territory open-ended and redundable

- fibre-optic communication lines for RSO and IVK MicroТEК of distant facilities of workshops # 408 and #409

- centralized visualization system (RSO) providing real time access to changeable parameters and collected archives

|